MACHINE TOOLS

MACHINING PROCESSES

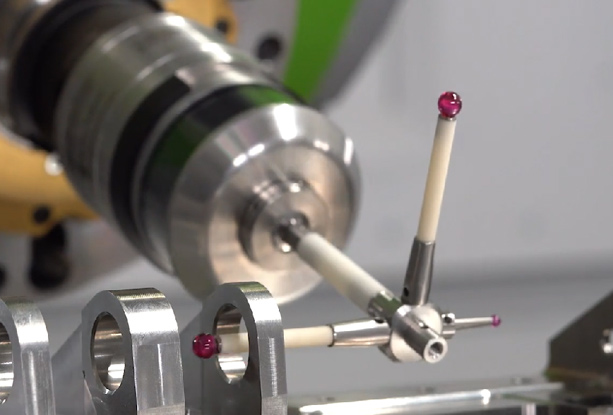

Precision Touch Probe

T25P is a Marposs high precision hard-wired probe through which any user, through automatically detection of machine axis position, can achieve part positioning and accurate part measurement. Based on piezoelectric technology, it guarantees unbelievable accuracy and a repeatability value within 0.25 µm (2σ).

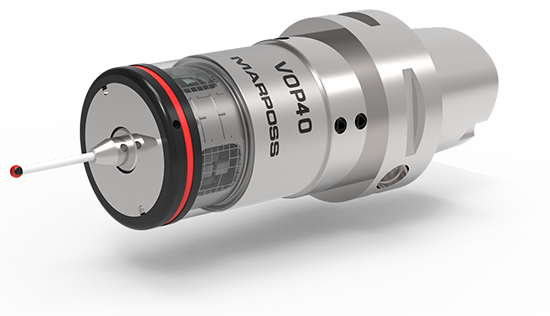

Compact Optical Transmission Probe

VOP40 is a compact probing system that thanks to the optical transmission allows the part to be measured, positioned and aligned in small and mid sized work centres and milling machines and in general all machines with a limited work area.

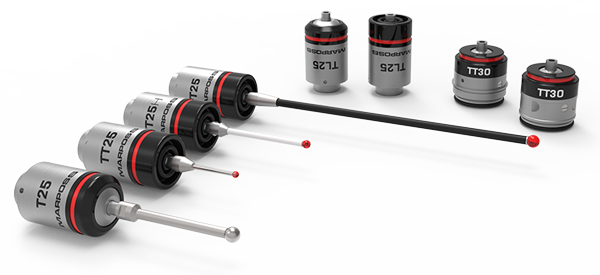

Touch Probe Line

The T and TT ranges of MIDA probes are high performance touch probes and cover every type of machine tool and application. Using these probes to define work-offset and to inspect work-piece on machine helps to reduce the quantity of rejected parts.

Marposs

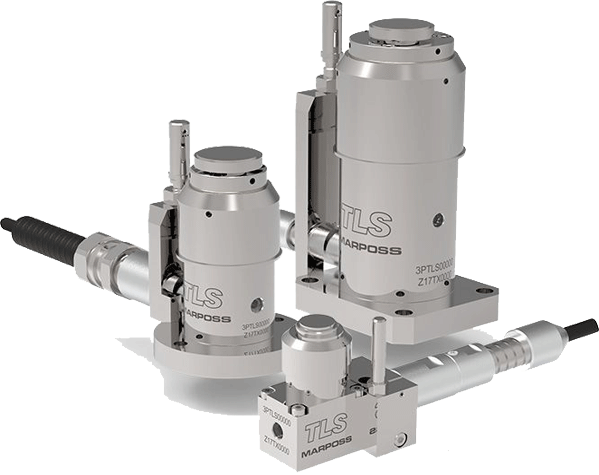

In the contact tool setter application field, the TLS line offers a complete range of probes for presetting tool lengths, and performing tool integrity and wear checks inside machining centres.

Mida laser P

TOOL PRESETTING

The TS30 Tool setter is a compact application for tool presetting on the bench of machining centers with an integrated interface.

TS30 90new

Marposs

The TS Line includes dedicated probes for presetting contact tools and tool measurements and integrity inspections. TS Line probes enable users to maintain part dimension tolerances under control, thanks to the cutting edge wear…

Why choose Upanal CNC

solutions for Marposs

Partners since 2021

Machining Rotary Solution

Zero backlash rotary table

Constant servicing and maintenance solutions

On the job Skill upgradation Training Facility

Demo trial facility

Advanced infrastructure

For over a year now, the association between Marposs and Upanal CNC has been partnering together and this relation is built exclusively on trust and quality assurance which Marposs has never failed to assure us with. It is common for machineries to have issues anytime, hence the need for constant vigilance. Our super quick and efficient team is ready round the clock to assist in troubleshooting whenever needed. We provide on the job training to the operator and programmer to help them constantly upgrade their skills and bridge the gap. The knowledge-sharing sessions are a way to keep the employees up-to-date with every changing trend.

We are known within the industry for providing the best rotary solutions for machines. Our products are crafted after endless research and planning, hence the guaranteed assurance. Our rotary tables have zero backlash which ensures a competitive edge with higher market standards and universally higher rate of acceptance. Consumers can exclusively assess the components at our demo trial facility in Peenya for quality and service assurance. We offer additional facilities like tool measurement and test the systems with contact and contactless technology in addition to providing solution and service check for process monitoring of different types of sensors.

Exclusive partners for

BFW Machines