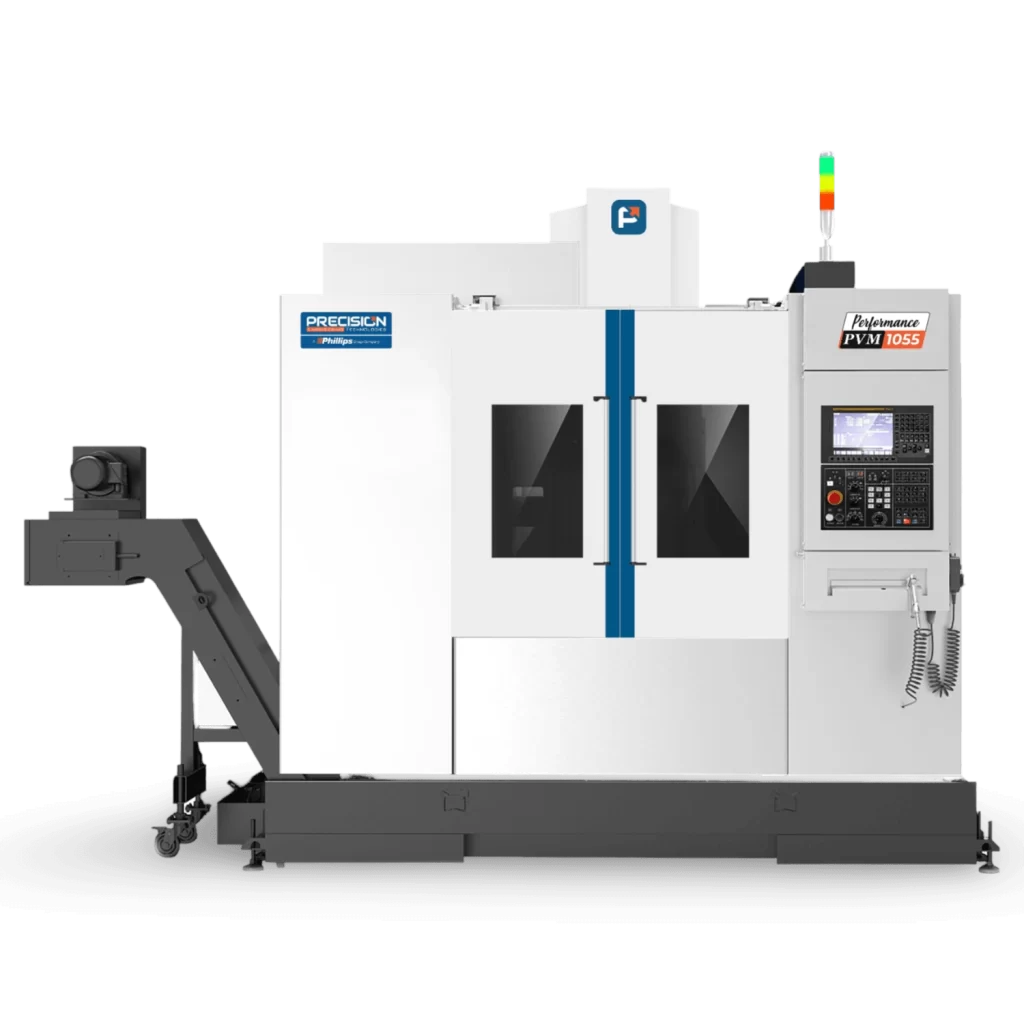

Vertical Machining Center - PVM Series

Get in touch

High-Performance CNC Vertical Milling Machines, 3 Axis Milling and 5 Axis Milling Machines.

The PVM Series CNC Milling Machine is a leading industry Vertical Milling Machine designed for unmatched precision and productivity. As a versatile Vertical CNC Milling Machine and VMC Machine, it offers exceptional performance for industries such as automotive, aerospace, oil & gas, and mold industry applications. This advanced Vertical Machining Center delivers consistent results with minimal maintenance, making it a top choice for manufacturers seeking reliability and competitively priced CNC machines in India.

Why Choose the PVM Vertical CNC Milling Machine?

- High-End Technology: Equipped with advanced 3-axis CNC machine technology for superior precision.

- Robust Engineering: Designed to handle complex geometries and challenging materials with ease.

- Versatile Applications: Ideal for 3-axis milling of intricate components and adaptable for 5-axis CNC machines for advanced operations.

- Competitive Pricing: PETECH offers the best CNC milling machine price without compromising on quality.

Advantages of the PVM CNC Milling Machine:

- High Accuracy and Repeatability even in challenging applications.

- Faster Production Cycles with optimized cutting paths.

- Versatile Machining Capabilities – from 3-axis milling to future-ready adaptability for 5 axis CNC machines.

- Lower Operating Costs with energy-efficient design.

- Operator-Friendly Interface for reduced setup time and enhanced usability.

Get the Best CNC Machine Price in India

If you’re searching for a Vertical CNC Milling Machine, VMC Machine, or 5-axis CNC machine, PETECH offers industry-leading solutions at competitive prices.

Specifications

Brochure

Specifications

PVM Series – Small Frame Specification

| SECTION | DESCRIPTION | UNIT | PVM 650 | PVM 855 | PVM 1055 |

|---|---|---|---|---|---|

| Table | Table Size | mm | 850 X 400 | 1000 x 500 | 1100 x 500 |

| Max. Load Capacity | kg | 400 | 600 | 600 | |

| T-Slots | mm | 3 X 18 – 100 | 5 x 18-100 | 5 x 18-100 | |

| Dist. Table Surface to Spindle | mm | 100 – 600 | 120 – 720 | 120 – 720 | |

| Spindle | Spindle Taper | type | BBT40 | BBT40 | BBT40 |

| Spindle Speed | rpm | 12000 | 12000 | 12000 | |

| Spindle Driving Method | type | Direct | Direct Drive | Direct Drive | |

| Main Spindle Power Output | kw | 7.5 / 11 | 11 / 15 | 11 / 15 | |

| Max. Spindle Torque | nm | 95.5nm @ 2000 | 118 @ 1500 | 118 @ 1500 | |

| Travel (X/Y/Z) | mm | 650 / 400 / 500 | 850 / 550 / 600 | 1000 / 550 / 600 | |

| Feed | Rapids Rate (X/Y/Z) | m/min | 48 / 48 / 32 | 48 / 48 / 36 | 48 / 48 / 36 |

| Feed Rate (X/Y/Z) | m/min | 12 | 12 | 12 | |

| Guideways | type | Ball | Roller Guideways | Roller Guideways | |

| ATC | Number of Tools | nos. | 20 | 24 (30 / 32) | 24 (30 / 32) |

| Max. Tool Dia. (W.T. / W.O.) | mm | Ø78 / Ø120 | Ø78 / Ø120a | Ø78 / Ø120a | |

| Max. Tool Length | mm | 220 | 300 | 300 | |

| Max. Tool Weight | kg | 8 | 8 | 8 | |

| Tool Change Time | sec | 2.5 | 2.5 | 2.5 | |

| Accuracy | Positioning | mm | 0.008 | 0.008 | 0.008 |

| Repeatability | mm | 0.004 | 0.004 | 0.004 | |

| Power Supply | Air Consumption | bar | 6~8 | 6~8 | 6~8 |

| Electric Power Supply | kva | 15 | 21 | 21 | |

| Voltage | v/hz | 380v±10% 50hz | 380v±10% 50hz | 380v±10% 50hz | |

| Machine | Machine Size | mm | 2100 X 2100 X 2550 | 2650 x 2700 x 2850 | 2650 x 2700 x 2850 |

| Weight | kg | 4100 | 4500 | 5000 | |

| Controller | type | Mitsubishi / Fanuc / Siemens | Mitsubishi / Fanuc / Siemens | Mitsubishi / Fanuc / Siemens |

Brochure

PVM BT 40 Brochure

PVM BT 50 Brochure

PVM 1370 – PVM 1570 Brochure